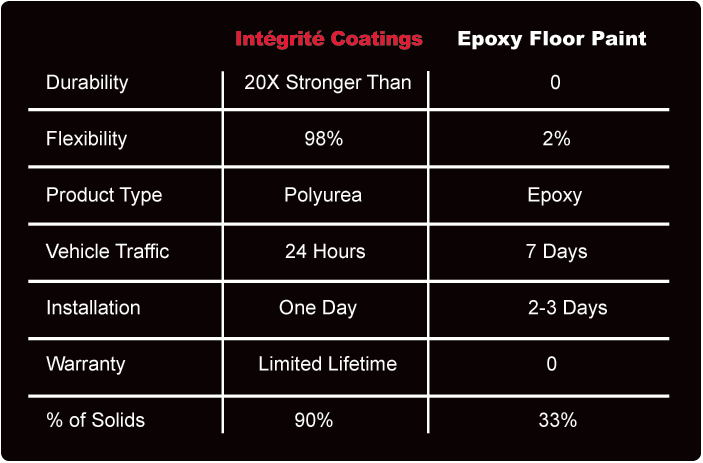

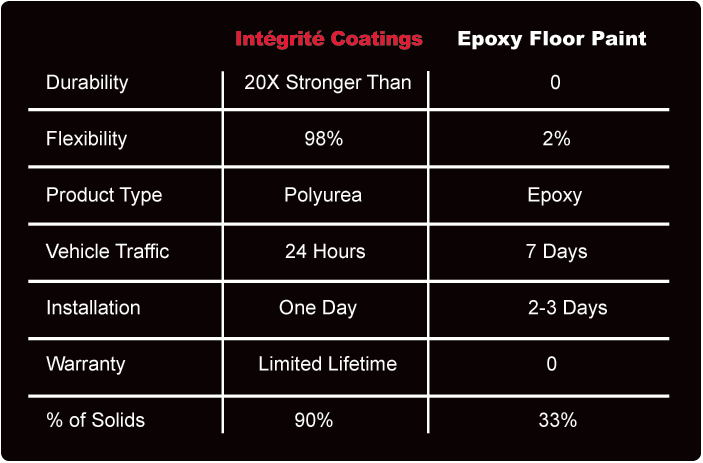

Epoxy Just Doesn't Compare.

When measured against Intégrité™ Polyurea, epoxy products can’t compare. Polyurea is 20x stronger than epoxy, making it last a lifetime longer even as it takes more punishment. It’s also 98% more flexible, flowing with the natural movement of concrete rather than cracking or peeling over time as epoxy does.

Polyurea is much faster as well—it takes only 1 day to install, can handle foot traffic in 4-8 hours and vehicle traffic within 24 hours. Epoxy can take 2-3 days to install, needs 24 hours just to handle foot traffic, and a full 7 days before vehicle traffic. For even more convenience, polyurea can be used any time of year, at temperatures between 0-120 degrees, while epoxy requires 60-80. Polyurea even has ultra low VOCs, both making it better for the environment and giving it minimal to no odor. Polyurea is simply better in every possible way.

|